CWT Service Provider

The qualified craftsmen at Cool Water Technologies have been installing, maintaining and restoring cooling towers for generations. We take pride in our work and value our relationships with our customers. We have the experience and equipment to handle even the most unique projects. Our services include a full range of solutions from basic maintenance, installation to restoration. We combine quality craftsmanship with structural engineering expertise to offer a full range of cooling tower services.

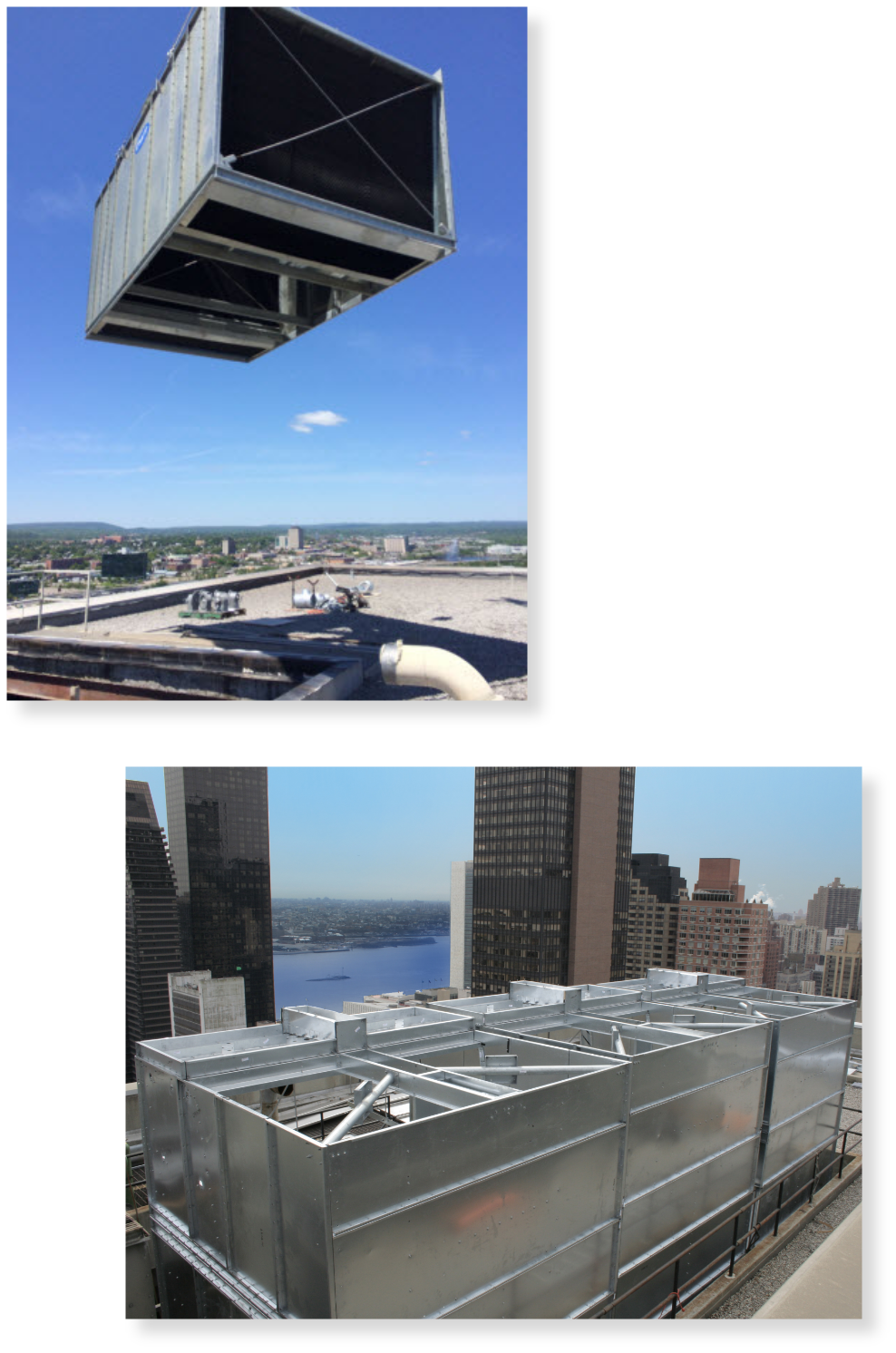

Installation

Five generations of experience in the New York tri-state area equals thousands of installations. This allows us to custom-fit the best tower to your precise requirements, using the most advanced controls, to make your tower efficient and worry-free. Cool Water Technologies installs cooling towers made by CWT and all other manufacturers. We’re on the job around-the-clock, seven days a week, ensuring that towers are kept at peak performance. From piping and filtration to electrical, tower management, and BMS, we go the extra mile when it comes to service.

We take into consideration every aspect of your project. Aside from customizing your tower we are accustomed to working around tight deadlines and schedules. If you are a place of business or residence that requires a prompt installation, weekend installation to avoid business interruptions, requires minimal noise, or even if you desire no crane to be used on-site because your business is dependent upon appearance we will work with you to make sure you can maintain business without any invasive presence.

Finding the right tower for you. CWT offers a wide range of tower designs and customization options for evaporative cooling towers for many systems. We will find the tower that best fits your building’s specific requirements.

Cooling tower essentials: Cooling towers come in either crossflow or counterflow options. Crossflow cooling towers enable water to flow vertically down the fill as air flows horizontally across. Counterflow cooling towers enable water to flow vertically down the fill as air flows vertically up. Cooling towers operate by either gravity distribution or pressurized spray systems to distribute water over the fill. Your local CWT technician will determine which tower series is ideal for your project. Contact your Cool Water Technologies representative today.

Restoration

Rebuild your tower for as little as 1/3 the cost of a new tower. Write off costs immediately as a maintenance expense. Recover lost cooling capacity and regain your cost efficiency.

CWT guarantees maintaining your tower’s designed thermal performance. As a result, your tower may exceed its original performance while running cheaper with new technologies such as Cool Water Technologies’ iD.

Cool Water Technologies provides full metal fabrication services for structural repair and replacement. Our experience and equipment handles even the most unique projects resulting in a full range of solutions for basic restoration needs. We restore the inner integrity of your cooling tower. CWT will make the best of the situation by offering speedy and affordable restoration. Rebuilding your tower to fit your needs may require custom parts. We make a full range of specialty parts, including custom fittings according to your specifications. With operating facilities of 200,000 square feet, CWT warehouses a variety of machinery and maintains a metal shop where our craftsmen can manufacture off-site fabrications. All employees of Cool Water Technologies are union members, as a result they all share the same goals and work ethic, and provide unparalleled service to meet the highest standards.

The Best Knowledge Base

Available

We maintain an extensive database of years of cooling tower work. That means proven solutions are at your fingertips.

The Best Workforce

Available

All skills and crafts are represented, so all your tower needs are available, from sheet metal work to comprehensive piping improvement, demolition and cleaning, protective coatings, thermal assessment, and replacement or improvement of tower controls.

The Best Technical Base

Available

Cool Water Technologies is continually inventing and improving tower performance, design and function. We are a fast moving company that realizes that innovation is the key to better service.

Special Parts Fabrication

Custom Fittings Are No Problem

We make the full range of specialty parts, including custom fittings, sump heaters, sump heater controls, and Mechanical Float Valve Kits, according to your specifications.

Maintenance

Keep your cooling tower operating at peak efficiency. Reduce the potential for unplanned downtime due to equipment failure. Maximize the operating life of your evaporative cooling system. Cool Water Technologies maintains, repairs, and retrofits cooling towers made by Cool Water Technologies and all other manufacturers. Decades of experience for the maintenance of all major manufacturers’ towers equals thousands of repairs and retrofits enabling us to tailor your tower to your specific needs with the most advanced controls and the most efficient operation, making your tower easier to run. CWT’s long-standing knowledge allows us to efficiently maintain and prolong the life of your cooling tower, providing significant cost savings. CWT supplies cooling towers that are energy-efficient, reliable, and maintenance-friendly. Our custom fabrication parts department allows us to manufacture custom parts for your tower. From piping and filtration to electrical, tower management, and BMS, we go the extra mile when it comes to service.

Be familiar with new technology that can improve function and monitor your tower and prevent avoidable complications. Benefits to maintaining your tower include a smooth and reliable running tower, increased cooling tower life expectancy, and maintaining and potentially improving performance. Older, structurally sound cooling towers can be retrofitted with upgrade kits to conserve energy. CoolCore™ high-performance wet deck disperses water for maximum heat transfer, and minimizes drift, water loss, and excessive power consumption. Other improvements in performance for water distribution systems are to replace older, smaller nozzles or troughs with large-orifice, clog-free designs.

A well-maintained tower strengthens your entire cooling system allowing it to perform at optimum efficiency by conserving energy and water. Regularly scheduled maintenance ensures the efficiency and longevity of your cooling system while maintaining low operating costs. This is any building owner’s dream. Unfortunately, it is too easy to forget about your cooling tower. A cooling tower requires routine inspection and maintenance to continue performing as designed. Get the most out of your cooling tower by using a preventative maintenance schedule. This Maintenance Schedule is given to you with your original cooling tower kit. This schedule will specify what components should be checked and how often the components should be checked depending on the series and size tower, features and technology purchased. Remember, maintenance frequency varies greatly on the environment in which the tower operates, the condition of the circulating water, and the cleanliness of the ambient air used by the tower. Pay close attention to any precautionary instructions and never perform any service inside the cooling tower or near the fans or drives unless the fans and pumps are locked out and disconnected.

Items That Should Be A Part Of Your Maintenance Schedule

- Check the unit for unusual noise or vibration

- Inspect cold water basin

- Inspect spray nozzles

- Drain basin and piping

- Inspect air inlet louvers

- Check and the adjust water level in the basin

- Check the operation of the mechanical/motorized valve

- Check and adjust the bleed rate

- Check belt condition

- Adjust belt tension

- Check drive alignment

- Check motor voltage and current

- Lubricate fan shaft bearings, motor base adjusting nut

- Check Fan-bearing locking collars

- Clean fan motor exterior

- Check the fan motor for proper rotation

- Check the fan for rotation without obstruction

Manufacturing

With a 200,000 square-foot facility, we are the only tower manufacturer that makes our own advanced controls, wet deck and towers in a quality-controlled, in-house setting. In addition, since our towers are locally manufactured in New York, Tri-State area customers pay no long-distance freight charges.